Introduction

In the world of precision machining, every detail matters. From cutting tool selection to coolant delivery, manufacturers rely on high-performance solutions to achieve superior results. One critical but often overlooked component in machining is the coolant nozzle—the system responsible for directing coolant to the right place, at the right pressure, and at the right time.

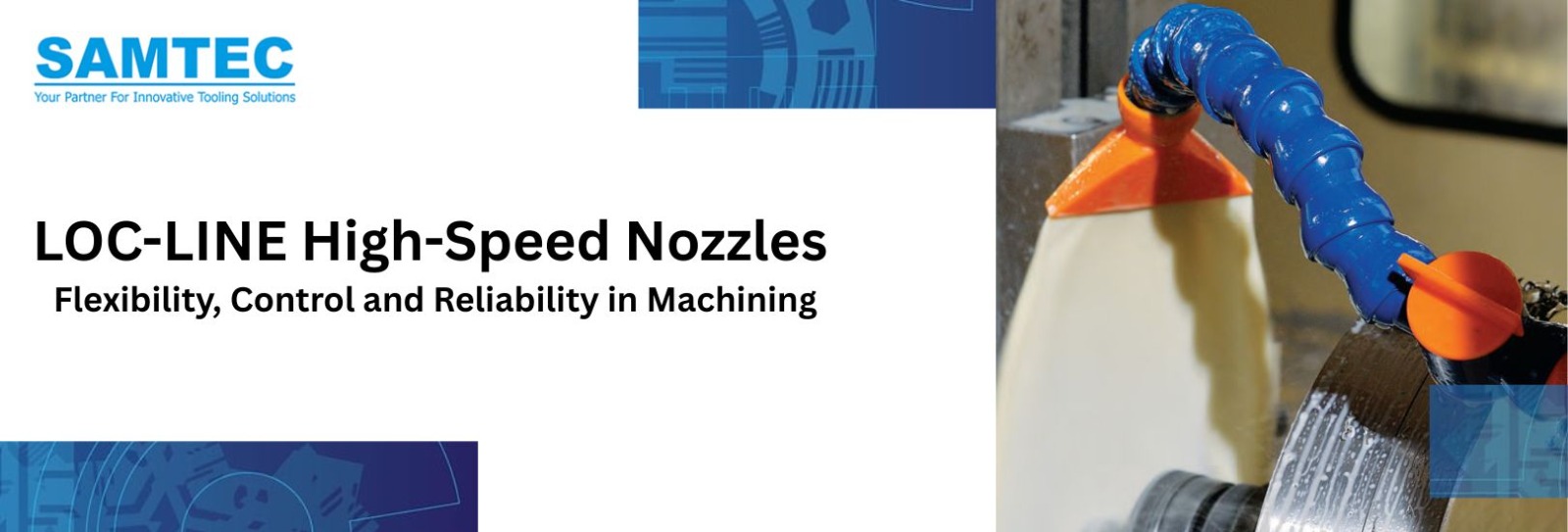

Among the most reliable and widely trusted options, LOC-LINE High-Speed Nozzles stand out for their flexibility, control, and durability. At Samtec Tools & Accessories Pvt. Ltd., we bring these nozzles to industries across India, offering manufacturers a proven solution for high-performance machining.

Why Coolant Delivery Matters

During machining operations, cutting tools face immense heat and pressure. Without proper cooling, tools wear out quickly, workpieces may deform, and surface finishes can suffer. Efficient coolant delivery ensures:

• Extended Tool Life – Reduces tool wear caused by friction and overheating.

• Improved Surface Finish – Prevents thermal damage and ensures smooth, accurate cuts.

• Faster Machining – Higher cutting speeds can be sustained with reliable cooling.

• Reduced Downtime – Less tool replacement and fewer machining interruptions.

This is where LOC-LINE high-speed nozzles make a significant impact.

What Are LOC-LINE High-Speed Nozzles?

LOC-LINE high-speed nozzles are modular coolant systems designed to provide precise coolant flow directly to the cutting edge. Unlike traditional rigid nozzles, LOC-LINE systems can be easily adjusted to direct coolant exactly where it’s needed, offering both flexibility and control.

The High-Pressure Turret (HPT) Nozzles, a part of the LOC-LINE family, expand the working pressure range up to 1,000 PSI, delivering the cooling power required for high-speed, heavy-duty machining applications.

Key Features of LOC-LINE High-Speed Nozzles

1. Flexibility in Positioning

LOC-LINE nozzles can be easily adjusted, moved, and locked into place. This allows operators to direct coolant flow precisely at the tool’s cutting edge or the most heat-intensive areas.

2. High-Pressure Capability

With HPT nozzles supporting pressures up to 1,000 PSI, they enable superior cooling performance for demanding machining operations.

3. Ease of Control

The modular design ensures quick adjustments without the need for tools, making setup and repositioning simple and efficient.

4. Durability

LOC-LINE systems are made from high-quality materials, designed to withstand tough machining environments, providing long-lasting reliability.

5. Safety and Reliability

With leak-resistant joints and stable flow, these nozzles minimize coolant wastage and deliver consistent performance.

Benefits in Modern Machining

1. Enhanced Productivity

By maintaining proper cooling even at high speeds, LOC-LINE nozzles allow manufacturers to increase cutting speeds without compromising tool life.

2. Versatility

Whether working with metals, plastics, or composites, these nozzles adapt to diverse machining operations.

3. Reduced Costs

Longer tool life and reduced downtime mean significant savings in both consumables and labor.

4. Improved Quality

Reliable coolant flow prevents overheating, ensuring precision and superior surface finishes across all parts.

Applications Across Industries

LOC-LINE High-Speed Nozzles are trusted in industries where precision and reliability are critical:

• Automotive – For engine components, gears, and transmission parts requiring high-speed cutting.

• Aerospace – For components where exact tolerances and heat management are non-negotiable.

• Industrial Manufacturing – For high-volume machining of heavy-duty machinery components.

• Tool & Die Making – Where cooling precision directly influences accuracy and finish quality.

Why Choose LOC-LINE Nozzles from Samtec Tools?

At Samtec Tools & Accessories Pvt. Ltd., we are committed to providing solutions that improve productivity and reliability in machining. By offering LOC-LINE High-Speed Nozzles in India, we ensure our customers benefit from:

• World-class quality with proven LOC-LINE technology.

• Special solutions like HPT nozzles for extreme pressure applications.

• Expert support to help manufacturers integrate these systems effectively into their machining setups.

The Future of Coolant Delivery

As machining technology advances, the role of precision coolant systems will only become more critical. High-speed machining, hard-to-machine alloys, and tighter tolerances demand efficient, flexible, and reliable cooling solutions. LOC-LINE nozzles, with their adaptability and performance, are already positioned as the industry standard for coolant delivery systems.

Summary

In modern manufacturing, success is determined by the ability to balance speed, accuracy, and cost-efficiency. The LOC-LINE High-Speed Nozzles empower manufacturers to achieve this balance by providing unmatched flexibility, control, and reliability in coolant delivery.

At Samtec Tools, we are proud to deliver these solutions, enabling our customers to reduce downtime, extend tool life, and improve machining performance. With LOC-LINE nozzles, precision is no longer just a goal—it’s a guarantee.